In the tangled industry of cable maintenance where accuracy and durability are paramount, the utilization of cutting-edge tools like wire rope lubricators as well as wire cleaners has become indispensable. These new devices are essential to ensure that cables run well and last longer in an array of industries. This article discusses the importance of wire rope cleaners and oil lubricators in maintaining cables. We will also discuss their benefits and functions.

Understanding Wire Rope Lubricators:

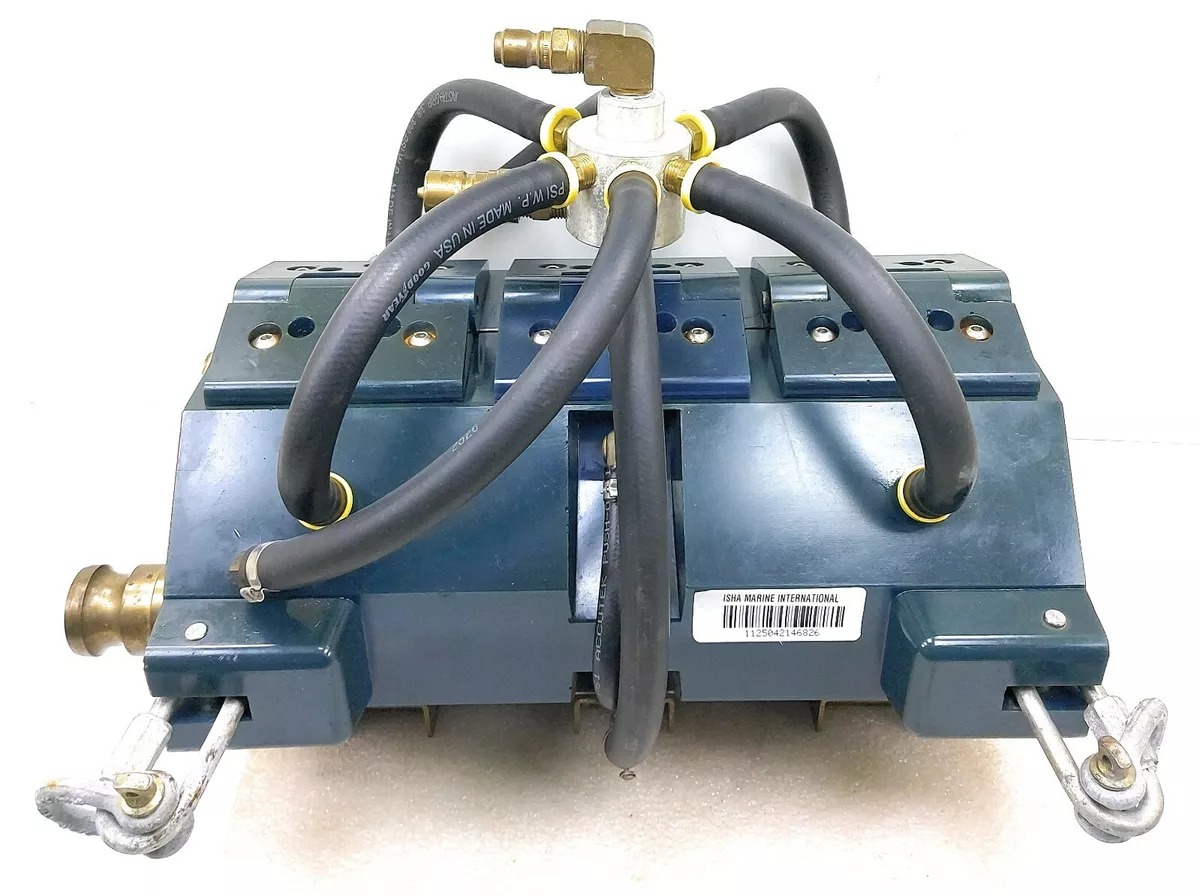

Wire rope lubricators can be described as tools that allow the lubrication process to wire ropes in a systematic manner. This is vital for stopping corrosion, reducing friction, and enhancing the durability of the cable. The lubricator distributes lubricant equally across the length and width of the wire rope in order to ensure that it is completely protected from wear.

How to keep cables clean by using wire cleaners

Parallelly, wire cleaners, sometimes referred to as cleaning agents for cables, help in keeping the hygienic condition of cables. They are specifically designed to eliminate debris, contaminants, and fluids that might build up on the cable during different processes. In conditions that are harsh the use of wire cleaning products is vital for ensuring optimal performance.

Optimizing Cable Lifespan:

The combination of lubricants for wire ropes and wire cleaners are significant in increasing the longevity of cables. Wire cleaners and lubricators are employed to apply lubrication and remove dirt. The cables are protected from corrosion, friction as well as other external forces. The integrity of the cable is maintained, resulting in increased operational efficiency and lower maintenance expenses.

Efficiency when applied

Wire Rope Lubricators are designed to be user-friendly and effective in application. They can be employed on various types and sizes of wire ropes, allowing for flexibility in the maintenance of cables. Automated and systematic lubrication removes the risk of a poor applications that manual techniques can cause.

Ability to adapt to challenging environments

In sectors where cables are exposed challenging environments, such as the ones used in construction, drilling, or maritime operations the ability to adapt wire rope lubricators and cleaners is crucial. They are specifically designed to withstand harsh conditions that makes them reliable instruments for maintenance of cables in different situations.

Cost-Effective Maintenance Solutions for

Implementing a proactive approach to cable maintenance by making use of lubricators for wire ropes and wire cleaners can be a cost-effective solution over the long term. The initial investment in these tools is not that significant compared to future costs, such as repairs and replacements because of poor maintenance. Know more at Wire Cleaning

Conclusion:

In the end wire rope lubricators, as well as wire cleaners stand as guardians of integrity of cables, providing precision, durability and maximum performance in various industries. The consistent application of lubrication and the removal of contaminants contribute to the longevity of cables, eventually making maintenance less costly and improving the efficiency of operations. Cables are still in use in critical industries, and using tools for maintenance of cables that will help maintain their reliability and performance is a must.